Advantages of vacuum environment: It can effectively remove bubbles in materials and avoid product quality problems caused by air mixing during the dispersion process (such as pinholes and shrinkage holes in coatings and adhesives), making it particularly suitable for processing materials sensitive to bubbles.

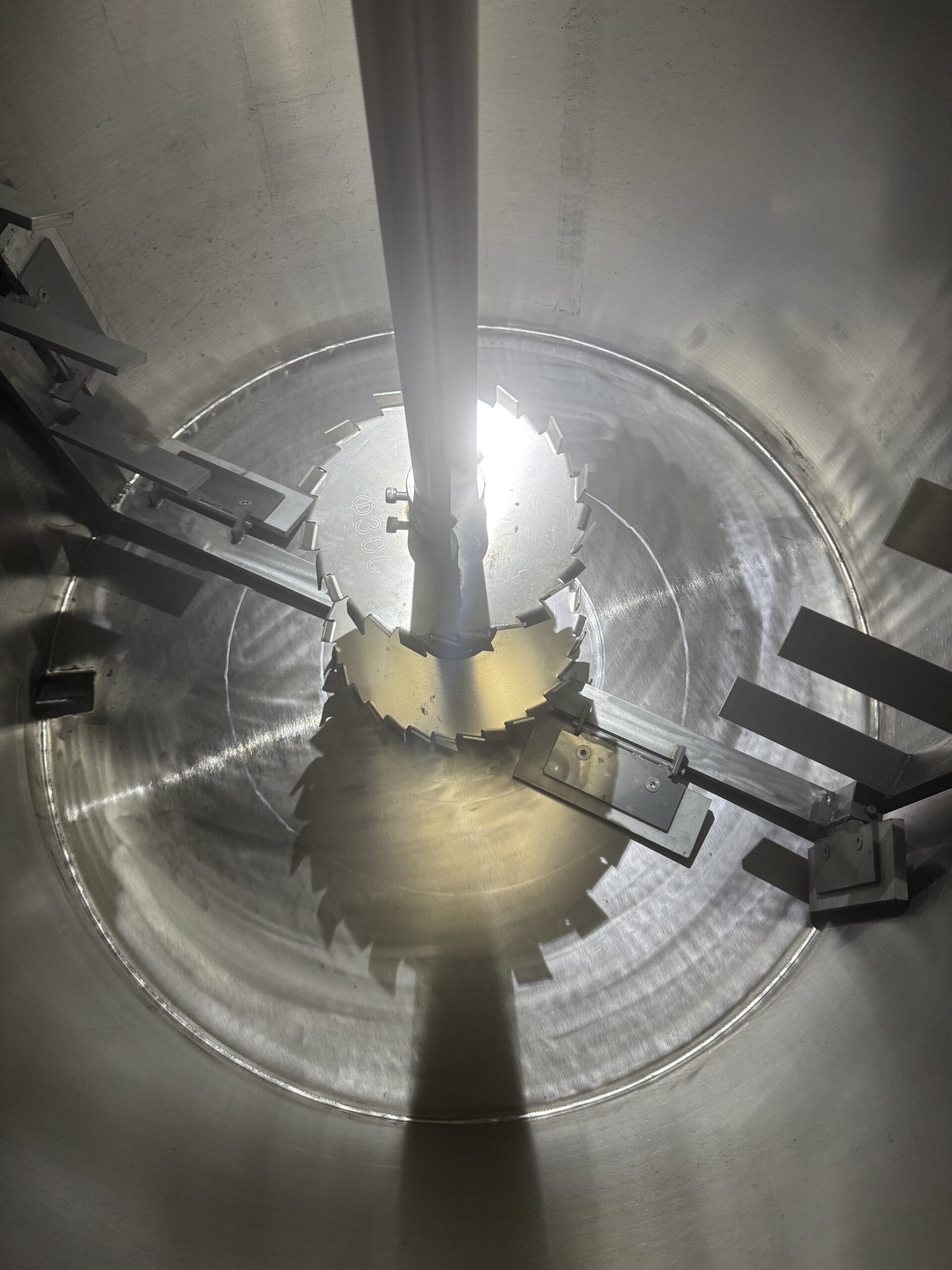

Good dispersion effect: Through high-speed stirring, shearing and other actions, materials (such as particles, powders, liquid-liquid mixtures) can be quickly and evenly dispersed, the particle size of materials can be refined, and the mixing precision can be improved. It is suitable for the dispersion of high-viscosity and high-solid-content materials.

Strong sealing performance: The equipment has good vacuum sealing performance, which can not only prevent material volatilization and environmental pollution, but also avoid the entry of external impurities to ensure material purity. It is suitable for processing materials that are easy to oxidize, toxic or highly volatile.

High operational controllability: Parameters such as stirring speed, vacuum degree and temperature can usually be adjusted to meet the process requirements of different materials. Some equipment is also equipped with automatic control systems, which facilitate precise control and mass production.

Wide application range: It is widely used in coatings, inks, adhesives, cosmetics, medicine, food and other industries, and can handle materials in various forms (liquid-liquid, solid-liquid, paste, etc.).

Type of shipping

When exporting Taibao machinery, sort out the nameplates, quantity, dimensions, and use standard export wooden crates. Determine the export time according to the delivery date and ensure proper packaging. Arrange for trucking to load the goods, check the weight, prepare customs declaration documents, complete the declaration, and cooperate with customs inspections. Finally, arrange for the delivery of the bill of lading, track the shipment, and maintain communication.

评价

目前还没有评价